The Gulf Cooperation Council (GCC) region, with its stunning architecture, luxurious resorts, and vibrant outdoor living, presents a unique challenge and opportunity for procurement managers. When it comes to outdoor furniture, the extreme climate – intense heat, high humidity, and occasional sandstorms – demands a meticulous approach to material selection and durability. This blueprint provides a comprehensive guide for procurement managers navigating the complexities of FF&E (Furniture, Fixtures, and Equipment) for outdoor spaces in the GCC.

1. Understanding the GCC Climate: The Ultimate Stress Test

The first step in any successful outdoor furniture procurement strategy for the GCC is a deep understanding of the local climate.

The scorching summer sun can reach temperatures exceeding 50°C (122°F), accelerating material degradation. UV radiation is particularly damaging, causing fading, cracking, and weakening of many common outdoor materials. High humidity, especially in coastal areas, can lead to corrosion of metals and mildew growth on fabrics. Furthermore, occasional dust and sandstorms abrade surfaces and clog mechanisms.

Key takeaway: Prioritize materials specifically engineered for extreme UV exposure, high temperatures, and corrosive environments.

2. Material Matters: Selecting for Longevity

The right material can mean the difference between furniture that lasts a decade and furniture that needs replacement after a single season.

a. Metals: Stainless Steel, Aluminum, and Powder-Coated Finishes

- 316 Marine Grade Stainless Steel: This is the gold standard for metal outdoor furniture in the GCC. Its high molybdenum content provides superior resistance to pitting and crevice corrosion, even in salty coastal air.

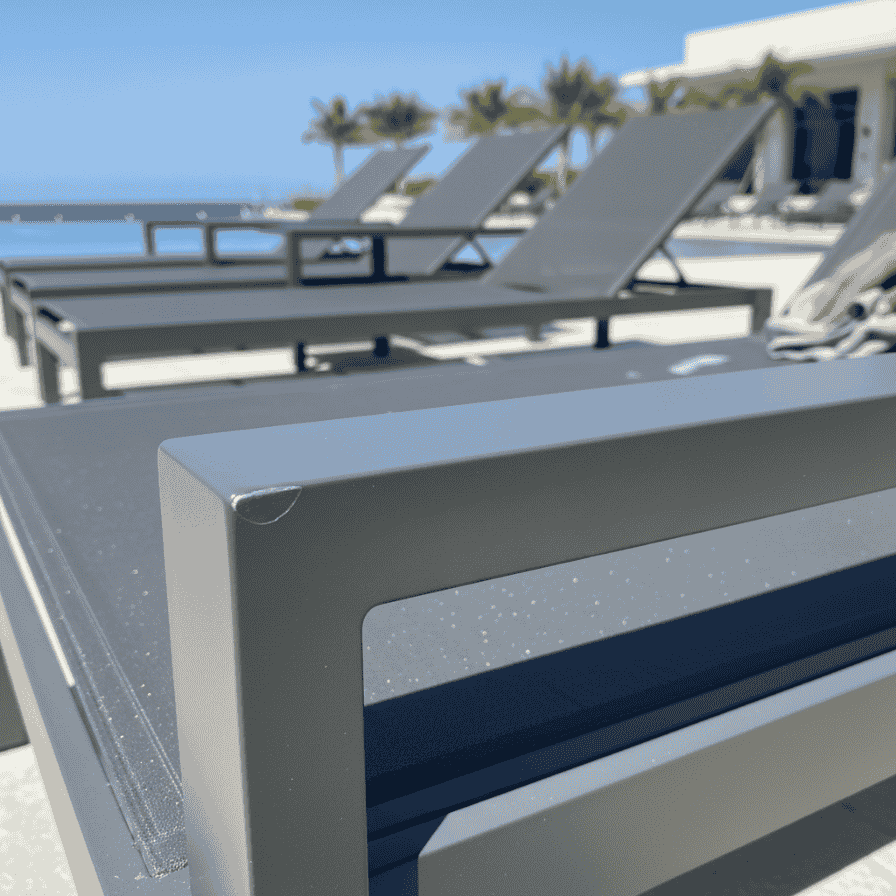

- Powder-Coated Aluminum: Lightweight, rust-resistant, and versatile, aluminum is an excellent choice when properly treated. Ensure the powder coating is of high quality (e.g., AAMA 2604 or 2605 standard) to prevent chipping, fading, and chalking under intense UV.

- Avoid: Wrought iron or standard steel without advanced galvanization and coating, as they are highly susceptible to rust in humid GCC conditions.

b. Woods: Teak and Other Hardwoods

- Teak: Renowned for its natural oils and dense grain, teak is exceptionally resistant to rot, pests, and weathering. It can withstand the GCC climate, developing a beautiful silver-grey patina over time if left untreated.

Other Hardwoods: While some other hardwoods can be used, they typically require more maintenance (sealing, oiling) to cope with the dry heat and intense sun. Ensure they are sustainably sourced and kiln-dried to prevent warping.

c. Woven Materials: Synthetic Wicker/Rattan

- High-Density Polyethylene (HDPE) Wicker: Unlike natural rattan or PVC-based synthetics, HDPE wicker is specifically designed for outdoor use. It’s UV-stabilized, resistant to cracking, fading, and mildew, making it ideal for the GCC. Ensure the weave is tight and consistent, and frames are made of aluminum.

d. Fabrics and Upholstery: Solution-Dyed Acrylic

- Solution-Dyed Acrylic (e.g., Sunbrella®): This is the industry benchmark for outdoor fabrics. The color pigments are added during the fiber extrusion process, meaning the color goes all the way through the fiber, making it incredibly fade-resistant. It’s also resistant to mold, mildew, and water.

Foam: Look for open-cell foam designed for outdoor use, which allows water to drain quickly, preventing mildew.

e. Tabletops: HPL, Ceramic, and Compact Laminate

- High-Pressure Laminate (HPL): Extremely durable, scratch-resistant, UV-stable, and easy to clean, HPL tabletops are an excellent choice for the GCC.

- Ceramic and Porcelain: Highly resistant to heat, scratches, and UV, ceramic tops offer a sophisticated look with robust performance.

- Compact Laminate: Similar properties to HPL, offering excellent weather resistance.

3. Construction and Craftsmanship: Beyond the Materials

Even the best materials can fail if the construction is poor.

- Welds: For metal frames, look for full circumference welds rather than spot welds, ensuring maximum strength and stability.

- Hardware: All fasteners, bolts, and hinges should be made of 316 marine-grade stainless steel to prevent rust streaks and structural failure.

- Joinery: For wooden furniture, traditional joinery techniques (mortise and tenon) are preferred over simple screws.

- Modularity: Consider modular designs that allow for easy replacement of individual components (e.g., slings, cushions) rather than the entire piece.

4. Supplier Vetting and Warranties

Partnering with the right supplier is crucial.

- Experience in the GCC: Choose suppliers who have a proven track record of providing outdoor furniture in the GCC and understand the specific demands of the climate.

- Testing Certifications: Request documentation of UV testing, salt spray testing, and load-bearing tests.

- Warranties: A robust warranty is a testament to a manufacturer’s confidence in their product. Look for warranties that specifically cover fading, structural integrity, and corrosion for at least 3-5 years, ideally longer for premium materials.

5. Maintenance and Lifecycle Cost

While focusing on durability, also consider ease of maintenance. Low-maintenance materials will reduce operational costs over the furniture’s lifecycle. Educate your maintenance teams on proper cleaning and care for each material type to extend lifespan.

Conclusion

Procuring outdoor furniture in the GCC is a strategic investment. By meticulously selecting materials, scrutinizing construction, vetting suppliers, and understanding lifecycle costs, procurement managers can ensure that their outdoor FF&E not only enhances the aesthetic appeal of a property but also delivers exceptional durability and value, standing strong against the region’s formidable climate for years to come.